Search

Search Criteria

Products meeting the search criteria

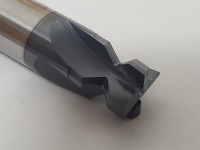

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA D1 CUTTER DIA 0.5" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.5"L1 OAL 2.5"..

$99.00

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA AlTiN CoatedD1 CUTTER DIA 0.5" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.5"L1 OAL 2.5"..

$109.00

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA AlTiN CoatedD1 CUTTER DIA 0.5" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.5"L1 OAL 3.0"..

$99.00

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA AlTiN CoatedD1 CUTTER DIA 0.5" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.5"L1 OAL 3.0"..

$109.00

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA D1 CUTTER DIA 0.625" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.625"L1 OAL 3.5"..

$140.00

Designed to the MIL-STD-1913 specificationsMill the entire Picatinny Rail in a single pass without tool changesType II: .005" radius tangent to angle and L4Cutting on entirety of concave form and OD flat at end4 helical flutes for better cutting action.005" max radius for all internal cornersSolid carbideCNC grounded in USA AlTiN CoatedD1 CUTTER DIA 0.625" (tol. +.000" / -.002")L2 LENGTH OF CUT .377" (tol +.001" / -.001") D3 MINOR DIA. .282 (tol +.001" / -.001")L6 0.021"L4 0.137"Type IID2 SHANK DIA 0.625"L1 OAL 3.5"..

$140.00

Showing 1 to 6 of 6 (1 Pages)